Coolant is a vital part of any liquid cooling system – just like oil is in your car’s internal combustion engine. And just like engine oil, the coolant needs to be changed regularly to keep your liquid-cooled PC in top shape. There are 5 crucial functions that the coolant performs in liquid cooling loops.

Transfers Heat

The first one is, of course, to transfer heat from the heat source to the radiator, where it’s cooled to the ambient temperature. This happens very rapidly and efficiently, but this is not the point of this blog post. You are reading this because you already know that liquid cooling is a superior way of cooling your high-end PC. But you still need to do a little bit of regular coolant maintenance.

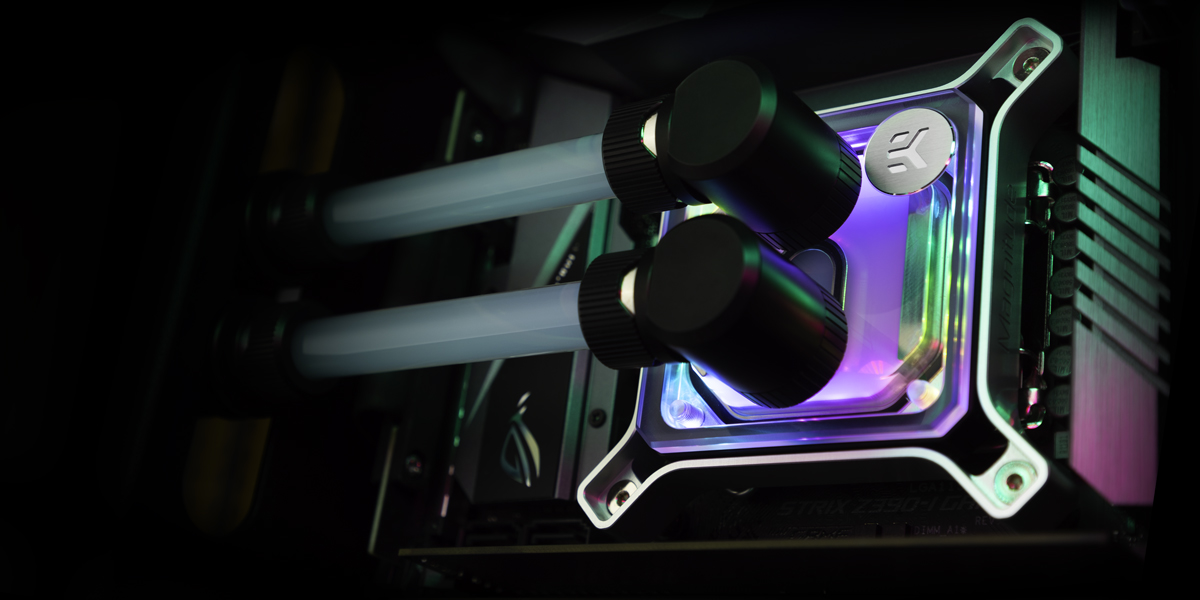

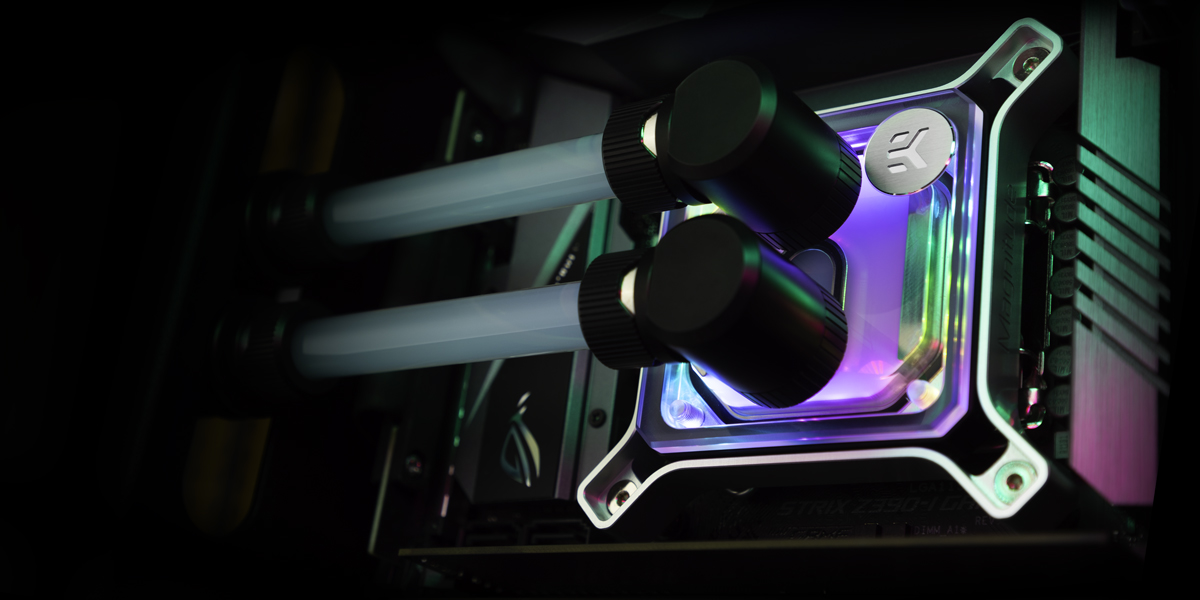

Protects from Corrosion

Purpose-made coolants, like our EK-CryoFuel, contain different components to perform their many functions. One of them is the corrosion inhibitor, which prevents metal components from degrading through the process of corrosion. But this inhibitor is constantly consumed in the process of performing its task. The more metals there are in the system, the higher the electrical potential is, and the more the corrosion inhibitor gets used. If there is not enough inhibitor substance in the coolant, corrosion may occur on the loop’s exposed metal components.

Prevents Biological Growth

Where there is water, there is life. Yep, even coolants are not safe from biological growth if not well-maintained. This is why top coolants also contain biological-growth inhibitors or biocides, which prevent microorganisms from growing inside the tubing and other liquid cooling components. By inhibiting biological growth like algae, they also prevent the appearance of unpleasant odors, discoloration, and clogging of the cooling channels. We are yet to meet a liquid cooling enthusiast who would want such things living and blooming in their loop.

Lubricates the Pump

Rotating components of liquid cooling systems, namely the pump motor, work hard to keep the system cool. Coolants lubricate them, but just like engine oil, they lose their lubrication power with time, which increases the possibilities of wear and defects.

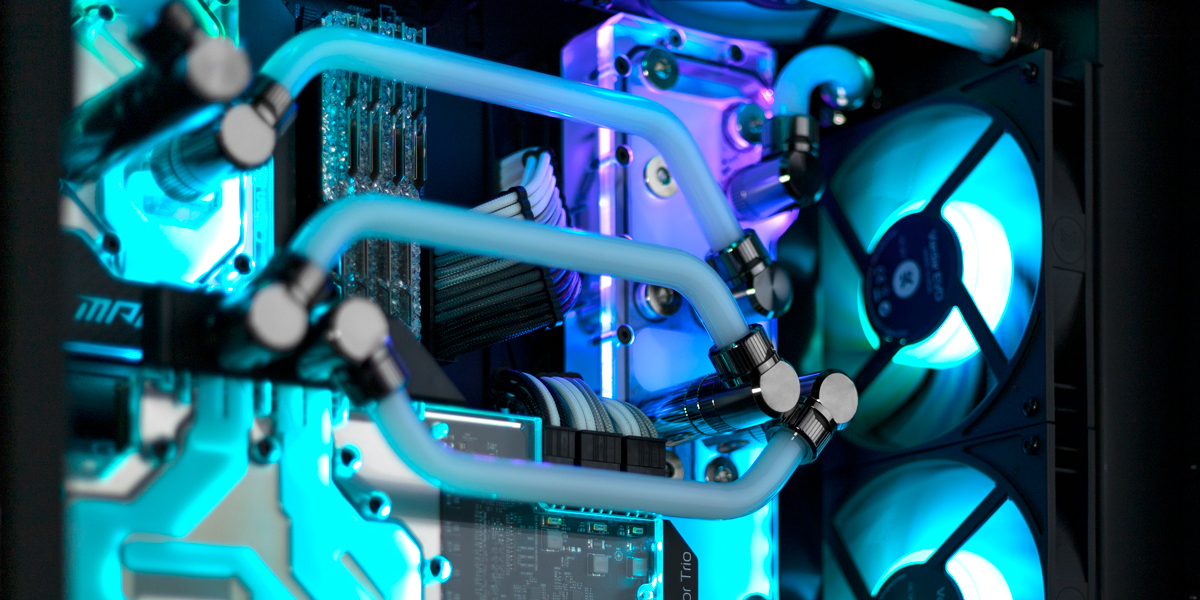

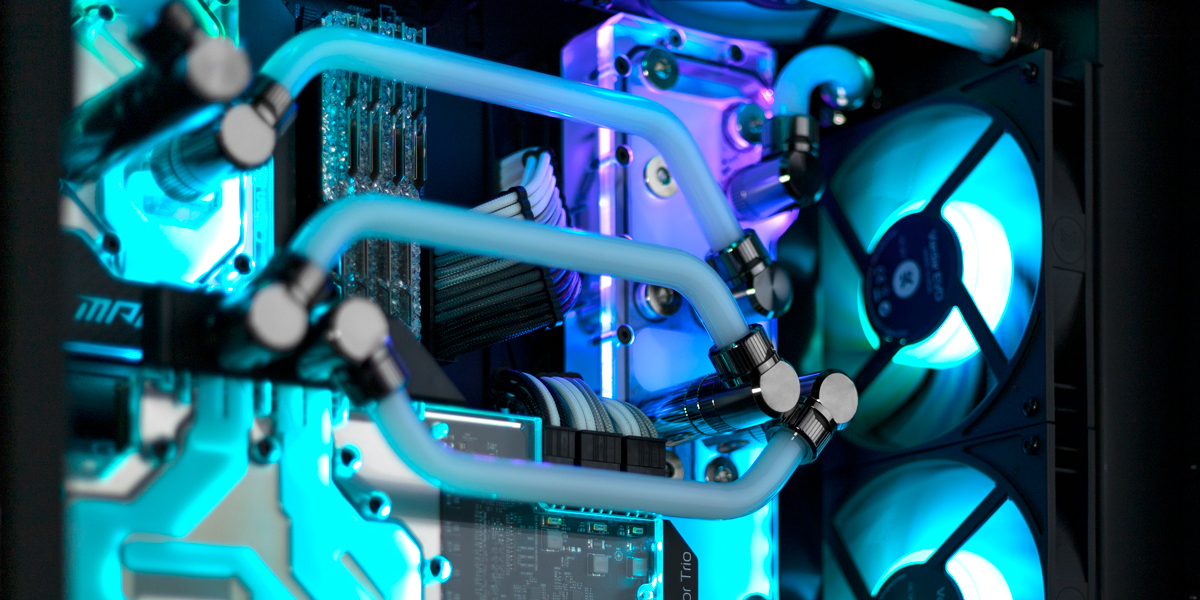

Brings Next-Level Aesthetics To Cooling Loops

Most of our customers who use colored coolants use them for aesthetics purposes. We all know how much pleasure an aesthetically complete build brings, especially when filled with EK-CryoFuel Solid coolants. Solid coolants are particulate-based coolants, and as the coolant’s ability to fight corrosion and biological growth diminishes over time, coolant fallout is also more likely to occur.

An Additional Reason To Maintain Your Loop: Coolant Evaporation

The coolant slowly evaporates through the tubing as it is exposed to heat. This phenomenon is the most prominent with clear soft tubing, where a noticeable drop of coolant level can be observed with time. Builds based on hard tubing don’t suffer from this issue, or the evaporation is negligible. Don’t forget: If you don’t have any leftover coolant, you should never top it off with pure distilled water since it will further weaken the coolant’s effectiveness.

When To Change the Coolant?

The coolant needs to be regularly changed to preserve its functionalities, like preventing corrosion, biological growth, and excessive wear on pumps. In the long run, purpose-made coolants also improve the performance, aesthetics, and lifespan of all liquid cooling components.

How often do you need to change the coolant then?

We recommend changing the coolant at least once per year to maintain its vivid color and basic functions discussed above. This doesn’t apply to certain special coolants. The unique, semi-transparent EK-CryoFuel Mystic Fog also contains UV reactive substances which can fade faster. For optimal visual performance, the recommended maintenance period is thus 6 months.

But even if not replaced every 6 months, the EK-CryoFuel Mystic Fog coolant will still perform its essential functions of protecting your loop for a full year. Similar goes for all coolants that contain UV additives, but the period when the UV reactivity fades varies based on the type and color of the coolant.

Visit the EK Online Shop to find the best coolant for your liquid cooling system

So, What’s the Main Takeaway Here?

The use of high-quality, purpose-made coolants with regular maintenance decreases unnecessary additional costs. By replacing your coolant as recommended, you can avoid downtime and damage to your liquid cooling loop, just like regularly replacing the oil in your car will keep things running smoothly for a long, long time.