Learn more about EK products

Visit EK Shop

Browse our high performance Quantum, Lignum and Classic product lines, Kits and Accessories.

Fluid Gaming Prebuilt PCs

Not the DIY person? Check out our fully water-cooled prebuilt PCs.

This website uses cookies. By continuing to use this website, you consent to the use of cookies in accordance with our Cookie Policy. By clicking “Accept All”, you agree to the storing of all cookies on your device. To learn more about our Cookie Policy and how to manage cookies, click here.

Every now and then we get a question how to apply the thermal pads or thermal grease correctly, therefore I decided to write a short blog post about it. First, I’ll present our TIM portfolio and then show a thing or two about the correct applying.

At EK we are using Ultra soft thermal pads from t-Global, which feature very good thermal properties along with great elasticity and elongation. They are self-adhesive on one side which is great because it makes the installation easier. We use thermal pads as the interface material between MOSFETs, inductor coils, circuit boards and the water block cold plates.

The thermal pads consist out of about 95% Aluminum oxide (Al2O3) and 5% Silicone resin. The thermal conductivity is 3,5 W/mK and operating temperature from -55°C up to 200°C.

Looking at the picture above, you can see that the thermal pad deflects by 45% when applying 40kPa of force. The thermal resistance is relatively steady so that tells us that it will perform well through the wide range of applied pressure.

When applying you must first make sure that you remove the protective foil from the both sides before putting it into place. The thermal pad is very soft, therefore it is easily cut to the desired dimensions.

The thermal pad should cover the whole surface, from which we want to dissipate the heat. Usually it helps if the thermal pad is a bit bigger than the previously mentioned surface. Using the right standoffs and designing we (EK) make sure that the gap between the copper cold-plates and the cooled elements on the PCB is just right. The bottom picture shows the “healthy” thermal imprint of the MOSFETs on the motherboard after one assembly/disassembly cycle of the monoblock.

When you remove the cooler you should clearly see the imprint of the edges of the elements on the PCB. When the edges aren’t visible you have no or bad contact. The contact can also be too good. You can observe that when you check if the motherboard/graphics card is severely bent in the area of the thermal pad. In extreme cases you can have a direct contact with the elements and that may lead to short circuiting your hardware.

Thermal grease is used mainly at contacts of the cold plate with GPU or CPU processor units. At EK we are using Thermal Grizzly Hydronaut and EK-TIM Ectotherm. Both are one of the best in its class and price range. The Thermal Grizzly Hydronaut is used at extreme overclocking because its operating temperature can be below zero degrees Celsius and the thermal conductivity doesn’t suffer. EK-TIM Ectotherm performs best at basic to extreme overclocking and is also easier to apply because it is less dense.

Thermal greases often consist of silicone compounds and must be applied in very thin layers. Because of the higher density, you must apply Thermal Grizzly Hydronaut thermal grease with applicator and cover the whole surface of the chip. At EK-TIM Ectotherm it is enough just to apply about two rice grains of the grease, depending on the chip size, on the center of the chip. The cold plate from the cooler will expand if it’s installed correctly.

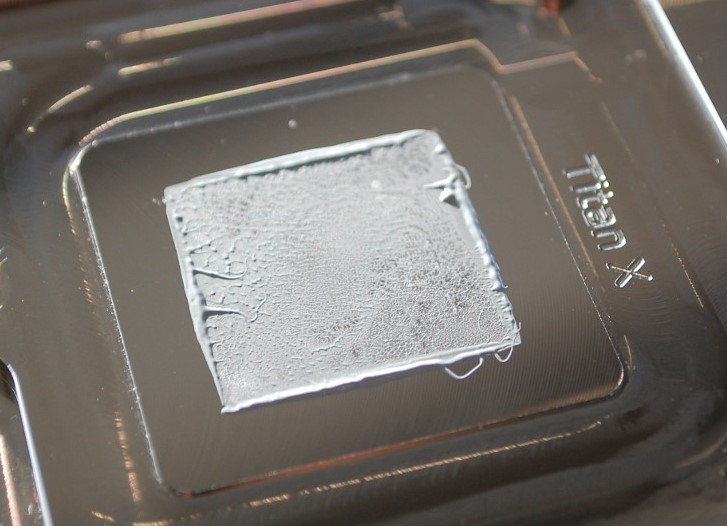

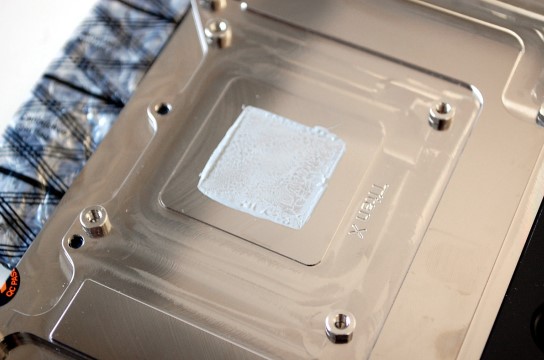

Below you can see the examples of good contacts when using EK-TIM Ectotherm thermal grease. As a reference, we took a contact on the Titan X GPU water block cold plate:

There is a chance that you apply too much thermal grease on the chip. In case of very dense material of the grease and thick applying of it, can result in poor thermal performance or even severely bent circuit board, which may lead to damage on the hardware.

We can summarize that choosing the right TIM is very important. You must beware that you take the right thickness (in case of thermal pad) and applying method (in case of thermal grease). If these conditions are taken into account, you can expect your hardware to run flawlessly even at high overclocks.

Browse our high performance Quantum, Lignum and Classic product lines, Kits and Accessories.

Not the DIY person? Check out our fully water-cooled prebuilt PCs.

Gigabyte Bench Table by Phenom Design

Gigabyte Bench Table by Phenom Design

Trackbacks & Pingbacks

… [Trackback]

[…] Read More to that Topic: ekwb.com/blog/how-to-correctly-apply-thermal-interface-material/ […]

… [Trackback]

[…] Information on that Topic: ekwb.com/blog/how-to-correctly-apply-thermal-interface-material/ […]

… [Trackback]

[…] Find More here to that Topic: ekwb.com/blog/how-to-correctly-apply-thermal-interface-material/ […]

… [Trackback]

[…] Find More on that Topic: ekwb.com/blog/how-to-correctly-apply-thermal-interface-material/ […]

… [Trackback]

[…] Information to that Topic: ekwb.com/blog/how-to-correctly-apply-thermal-interface-material/ […]

… [Trackback]

[…] Read More Info here on that Topic: ekwb.com/blog/how-to-correctly-apply-thermal-interface-material/ […]

… [Trackback]

[…] There you can find 4234 additional Information on that Topic: ekwb.com/blog/how-to-correctly-apply-thermal-interface-material/ […]

… [Trackback]

[…] Find More Information here to that Topic: ekwb.com/blog/how-to-correctly-apply-thermal-interface-material/ […]

… [Trackback]

[…] Here you will find 16804 additional Information on that Topic: ekwb.com/blog/how-to-correctly-apply-thermal-interface-material/ […]

… [Trackback]

[…] There you will find 54735 more Info to that Topic: ekwb.com/blog/how-to-correctly-apply-thermal-interface-material/ […]

… [Trackback]

[…] Find More on that Topic: ekwb.com/blog/how-to-correctly-apply-thermal-interface-material/ […]

… [Trackback]

[…] Information to that Topic: ekwb.com/blog/how-to-correctly-apply-thermal-interface-material/ […]

… [Trackback]

[…] Find More Info here to that Topic: ekwb.com/blog/how-to-correctly-apply-thermal-interface-material/ […]

Comments are closed.