Learn more about EK products

Visit EK Shop

Browse our high performance Quantum, Lignum and Classic product lines, Kits and Accessories.

Fluid Gaming Prebuilt PCs

Not the DIY person? Check out our fully water-cooled prebuilt PCs.

This website uses cookies. By continuing to use this website, you consent to the use of cookies in accordance with our Cookie Policy. By clicking “Accept All”, you agree to the storing of all cookies on your device. To learn more about our Cookie Policy and how to manage cookies, click here.

Water blocks may be disassembled for cleaning purposes on an occasional basis. The warranty is not rendered void on dis-assembly of the water block, but the customer loses the EK leak-free guarantee which comes with a factory tested water block. An old, but soft toothbrush is an excellent cleaning tool!

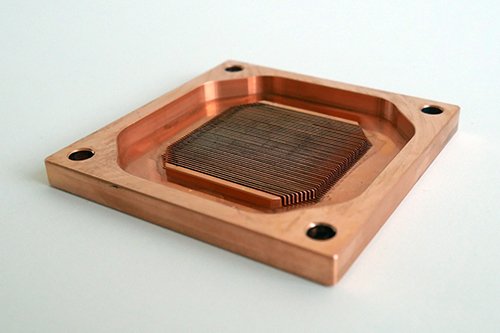

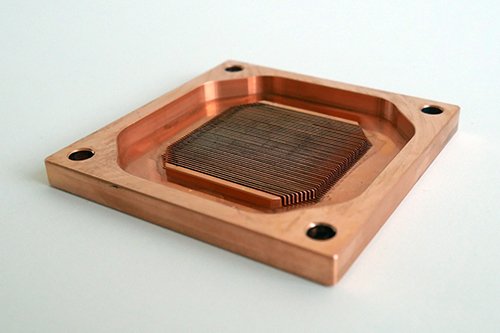

Cleaning bare copper

When cleaning bare copper is it recommended to use slightly acidic cleaning agents which include the following organic agents:

Certain food can also be used for cleaning copper:

5% vinegar is enough to kill 99.9% of algae and bacteria that could be present on copper in not maintained cooling loop as well.

Upon cleaning, it is necessary to flush the water blocks in water and rinse them with distilled water. After rinsing, we recommend wrapping the water blocks in paper towels until completely dry. It is nearly impossible to avoid naturally occurring copper tarnishing (oxidation) as the oxidation will reoccur the moment the copper is cleaned of the all oxides.

Cleaning nickel plated copper

When cleaning nickel plated copper, it is forbidden to use any aggressive chemicals (or vinegar) or rough materials as you may damage the plating and thus void the warranty. Please note also that due to presence of dye additives and other chemicals, the nickel layer may also become discolored/stained over a period of time. However, the staining is normally reversible by simple flush and rinse.

Cleaning the nickel plated copper should consist of these steps:

EK recommends the use of automotive soft, non-abrasive metal polish creams. After you finish using other cleaning methods, give the nickel plating a good polish with a non-abrasive metal or chrome polish. Apply a small amount of polish to a cloth or to the surface of the nickel. Wipe the entire surface of the nickel with the polish, using small circular motions, until it looks shiny and clean. Use another clean cloth to remove the remains of the polishing paste from the surface. Always rinse with distilled water after you are done with polishing.

Cleaning acrylic (Plexi) glass tops

Acrylic will fail prematurely if subjected to even small amounts of alcohol, acetone or other aggressive chemicals. Please do not use anything but warm, soapy water and a toothbrush to clean the acrylic (plexi) glass water block tops and reservoir tubes. Using aggressive chemicals will surely void your warranty!

Algae- or dirt deposits may be rubbed out using a soft cloth in combination with warm, soapy water. Rinse with distilled water after cleaning.

Cleaning POM (Acetal) tops

POM (polyoxymethylene) or Acetal can withstand chemicals such as alcohol or acetone but EK recommend using these very sparingly as the drying chemicals will certainly leave some residue. Usually POM can be cleaned easily with just a soft cloth and warm, soapy water – without the use of any chemicals. Rinse with distilled water after cleaning.

Preventive steps:

Water blocks may be disassembled for cleaning purposes on an occasional basis. The warranty is not rendered void on dis-assembly of the water block, but the customer loses the EK leak-free guarantee which comes with a factory tested water block. An old, but soft toothbrush is an excellent cleaning tool!

Cleaning bare copper

When cleaning bare copper is it recommended to use slightly acidic cleaning agents which include the following organic agents:

Certain food can also be used for cleaning copper:

5% vinegar is enough to kill 99.9% of algae and bacteria that could be present on copper in not maintained cooling loop as well.

Upon cleaning, it is necessary to flush the water blocks in water and rinse them with distilled water. After rinsing, we recommend wrapping the water blocks in paper towels until completely dry. It is nearly impossible to avoid naturally occurring copper tarnishing (oxidation) as the oxidation will reoccur the moment the copper is cleaned of the all oxides.

Cleaning nickel plated copper

When cleaning nickel plated copper, it is forbidden to use any aggressive chemicals (or vinegar) or rough materials as you may damage the plating and thus void the warranty. Please note also that due to presence of dye additives and other chemicals, the nickel layer may also become discolored/stained over a period of time. However, the staining is normally reversible by simple flush and rinse.

Cleaning the nickel plated copper should consist of these steps:

EK recommends the use of automotive soft, non-abrasive metal polish creams. After you finish using other cleaning methods, give the nickel plating a good polish with a non-abrasive metal or chrome polish. Apply a small amount of polish to a cloth or to the surface of the nickel. Wipe the entire surface of the nickel with the polish, using small circular motions, until it looks shiny and clean. Use another clean cloth to remove the remains of the polishing paste from the surface. Always rinse with distilled water after you are done with polishing.

Cleaning acrylic (Plexi) glass tops

Acrylic will fail prematurely if subjected to even small amounts of alcohol, acetone or other aggressive chemicals. Please do not use anything but warm, soapy water and a toothbrush to clean the acrylic (plexi) glass water block tops and reservoir tubes. Using aggressive chemicals will surely void your warranty!

Algae- or dirt deposits may be rubbed out using a soft cloth in combination with warm, soapy water. Rinse with distilled water after cleaning.

Cleaning POM (Acetal) tops

POM (polyoxymethylene) or Acetal can withstand chemicals such as alcohol or acetone but EK recommend using these very sparingly as the drying chemicals will certainly leave some residue. Usually POM can be cleaned easily with just a soft cloth and warm, soapy water – without the use of any chemicals. Rinse with distilled water after cleaning.

Preventive steps:

Browse our high performance Quantum, Lignum and Classic product lines, Kits and Accessories.

Not the DIY person? Check out our fully water-cooled prebuilt PCs.

… [Trackback]

[…] Read More to that Topic: ekwb.com/blog/how-to-clean-water-blocks/ […]

… [Trackback]

[…] Read More on that Topic: ekwb.com/blog/how-to-clean-water-blocks/ […]

… [Trackback]

[…] Find More here on that Topic: ekwb.com/blog/how-to-clean-water-blocks/ […]

… [Trackback]

[…] Read More here to that Topic: ekwb.com/blog/how-to-clean-water-blocks/ […]

… [Trackback]

[…] Here you can find 84543 additional Info on that Topic: ekwb.com/blog/how-to-clean-water-blocks/ […]

… [Trackback]

[…] There you can find 15248 additional Info to that Topic: ekwb.com/blog/how-to-clean-water-blocks/ […]

… [Trackback]

[…] Find More on on that Topic: ekwb.com/blog/how-to-clean-water-blocks/ […]

… [Trackback]

[…] There you will find 52673 more Information to that Topic: ekwb.com/blog/how-to-clean-water-blocks/ […]

… [Trackback]

[…] Information on that Topic: ekwb.com/blog/how-to-clean-water-blocks/ […]

… [Trackback]

[…] Read More here to that Topic: ekwb.com/blog/how-to-clean-water-blocks/ […]

… [Trackback]

[…] Read More on that Topic: ekwb.com/blog/how-to-clean-water-blocks/ […]

… [Trackback]

[…] Find More Info here to that Topic: ekwb.com/blog/how-to-clean-water-blocks/ […]

… [Trackback]

[…] There you can find 31018 additional Information on that Topic: ekwb.com/blog/how-to-clean-water-blocks/ […]

… [Trackback]

[…] Read More on that Topic: ekwb.com/blog/how-to-clean-water-blocks/ […]

[…] 5% vinegar is enough to kill 99.9% of algae and bacteria that could be present on copper in not maintained cooling loop as well. Upon cleaning, it is necessary to flush the water blocks in water and rinse them with distilled water. via […]

PAX South 2016 Recap

PAX South 2016 Recap

Usually when cleaning the water blocks, there is a black residue left on the copper from what seems to be O-ring grease mixed with degraded rubber.

I take care to remove that, and grease the O-rings to keep the rubber lasting longer, and if i find that they are too thin or they are so brittle they have a crack, I replace them.

I like your guides, and I’d like it if you mentioned maintenance of the O-rings (cleaning, greasing and replacing) since they are absolutely essential for keeping the system leak-free.

What type of grease is used for the seals/rubber gaskets?

I use Trident LP20 pure silicone grease it’s made for diving o rings. It does a great job of lubricating any rubber products. You can buy a small 2 oz can from Amazon